Products

- Burn-in Sockets

- Socket / Connector Stock List

- High Power Thermal Sockets

- Custom Burn-In Sockets

- Test Contactors/Sockets

- Package/Chip Adapters

- Failure Analysis Sockets

- Production Prototype Sockets

- Memory Card SIM Connectors

- Receptacles/Socket Savers

- Thermal Solutions

- Y-SOL Solar Connectors

- Y-SOL4 FAT and CAT (Solar)

- H-Pin Probe (Compression)

- Burn-In Systems

- Burn-In Boards

- Burn-in Testing Services

- Contact Resistance Tester

- Prototype Precision Tooling

- Precision Machined Parts

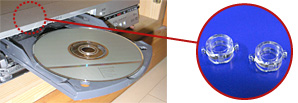

QMS Rapid Precison Plastic Prototypes

Since 1986 Enplas has had a subsidiary solely dedicated to rapid precision plastic prototyping. This subsidiary, Quick Mold Service (QMS), was a direct spin-off from their tooling department, thus ensuring the same quality that Enplas delivers.

QMS has the ability to deliver molded prototype parts in as little as 1 week, depending upon design specifications and volume requirements, with 95% of all parts taking no more than 4 weeks to deliver. The QMS method ensures simultaneous evaluation for fit, form, function, and assembly. These benefits are not possible with conventional machining and prototyping methods.

This ability to evaluate on several levels will save money and cut development time by up to 50%. QMS can mold all injection-molded engineering plastics used for mass production. QMS will provide dimensional data for each part prototyped. QMS can also offer the flexibility to accept material changes and design modifications. QMS offers prototype parts in quantities up to 10000 pieces and larger sample volumes can be negotiated. Parts are manufactured to your specifications, using your drawings. Drawings can also be transmitted electronically in IGES and DXF formats.

QMS has served many industries including medical equipment, sockets/connectors, electronics, optical devices, office automation, communications equipment, automotive products and many others. QMS manufactured averages over 200 prototype tools per month with the capacity to handle even more.

If your challenge is high-quality, precision parts in a hurry then QMS should be your first and only choice.

Featured Products

PH: (770) 424-6165 SKYPE: owenprill Email: Techconnectsales@gmail.com

Copyright © Techconnectsales.com All rights reserved